Last week we talked buttons and zippers. Both are pretty good clues to a garments date. When paired with the garments makeup; fabric, cuts, and seams you can rest assured you've got a pretty solid method of dating. (That is if no label is present, we'll talk labels soon.)

Time to peak at the undercarriage....

The sewing machine made its debut in the late 1700's, the first practical machine patented in the mid 1800's and by the 19th century the sewing machine was becoming a household object. Hand-sewn construction and machine-sewn construction coexisted for years, until the late 19th/early 20th century. When dating early garments its fabric type and cut of garment is useful.

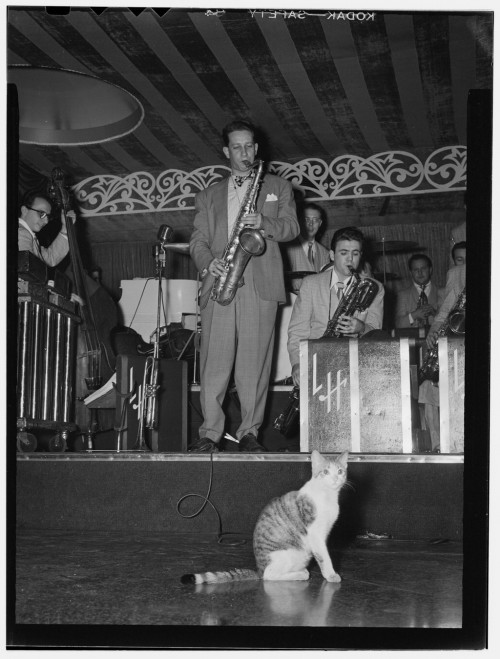

Top to bottom: French seam, Pinked seam, Serged seam.

French seams were used on turn of the century clothing through to the 1940's. In a French seam the raw edges of the fabric are fully enclosed providing for a neat finish. The seam is first sewn with the wrong sides together. The seam allowances are then trimmed and pressed. A second seam is sewn with right sides together, enclosing the raw edges of the original seam.

Pinked seams can be seen in most 1950's garments. They are recognizable by scalloped or teethed looking edge. Although pinking cutters were patented in 1893, the invention of the pinking shears by Benjamin Luscalzo is what popularized this seam. These shears allowed for a way to cut a garment without leaving the fabric to fray. That meant the time consuming french seam was no longer needed.

Serged seams have been around since the 1900's and in use by the 1920's. However it was a rarity The serger became affordable and mass produced by the 1960's making the over-locked stitch popular, still used today.

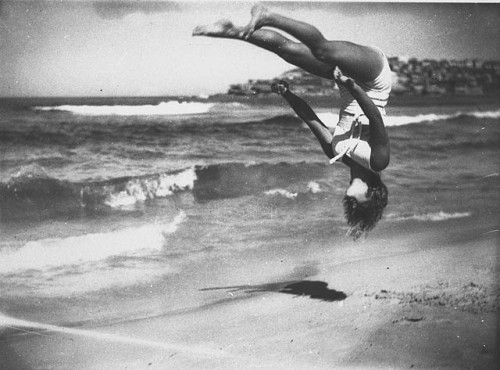

Top to bottom: Blind hem circa 1950's, Hem tape circa 1960's, Rolled hem circa 1980's

Certain

finishing techniques are also good clues in dating your piece. Hems were generous from the 40's to the 60's, often three or four inches deep and finished with hem tape and blind stitching.

Hem tapes were generally used by North American manufactures. Modern garments usually have a narrow, machine-rolled hem.

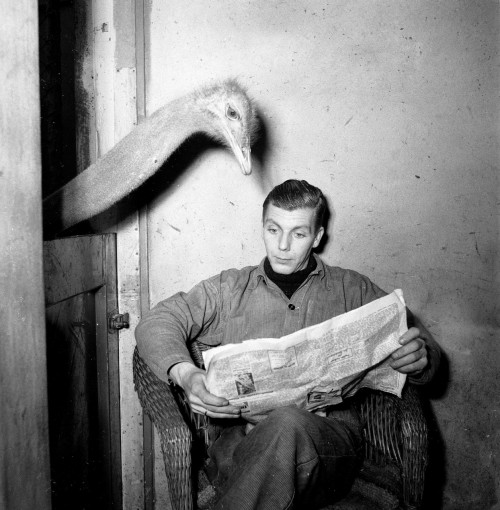

Armholes were most often tailored to the wearers arm and cut high, prior to the 1970's. From the 1930's to the 1950's three-quarter and seven-eighth sleeves were popular. If you should find diamond gussets in the armhole, its most likely 1950's. In the 1970's styles changed to a less body conscience form, sleeves became bloused or bell shaped. By the 1980's bloused sleeves reached its peak and gave way to the puffed sleeve often paired with shoulder pads. Think Dynasty.

Puffed sleeves scream 80's.

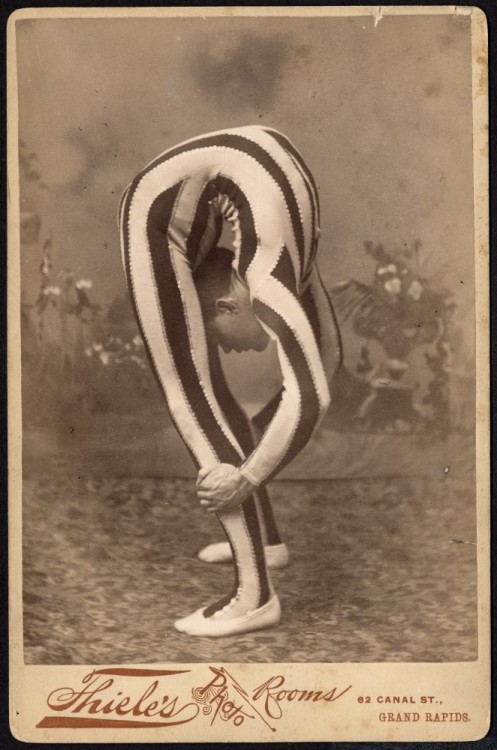

A garment's material is useful when discerning ages. In the 1980's there was a throwback to the lines and design of the 40's-60's dresses. Noting a garments material can be very helpful in differentiating the time periods.

Acrylic was developed in 1944. It was first used in the 1950's and still used today. It was originally used in outerwear but now is used most commonly in knits.

Rayon was developed in the 19th century to imitate silk. It was used extensively for lingerie and light summer dresses until the 1950's.

Nylon was developed in and used in the 1940's available mostly in stockings. It was not used in clothing until well after WWII and most often in lingerie.

Polyester has its roots in the 1920's but wasn't introduced in clothing form until the 1950's. It gained it's wide popularity in the 1970's. Polyester was durable, wrinkle free, and stain resistant. It could also be manufactured rather cheaply.

Spandex or Lycra was first produced in 1959 and can be seen in lingerie in the early 1960's. It's not until the 1980's that it became popular in clothing.

There are several ways to test a garments material type, one being the thread test. Another being the burn test. I've never used the burn test as I don't have a good track record with fire. Ask me about the "break a wine bottle in your sink" fiasco. Hint: I set my arm on FIRE.

My arm is fine, it was only "briefly" on fire.

To do the thread test all one needs is a magnifier or really really good eyesight. Find a seam where threads are sticking out, if you can pull a thread carefully that's preferable. Now break that thread.

- Cotton- breaks easily and have fuzzy, uneven ends.

- Linen-threads will snap when broken, ends are pointed and uneven.

- Wool-curls when broken.

- Silk-uneven clean ends when broken.

If you are brave enough to try a burn test use a small clipping from a seam. Hold the fabric with tweezers (not fingers). It's best to burn fabric over metal dish with water in the bottom.Some fabrics ignite quickly and melt, so please be careful.

- Acrylics-burn readily. A match acrylic can ignite the fabric which will burn rapidly unless extinguished. The ash is hard. The smell is acrid or harsh.

- Nylon-melts and then burns rapidly if the flame remains on the melted fiber. If you can keep the flame on the melting nylon, it smells like burning plastic.

- Polyester- melts and burns at the same time, the melting, burning ash can bond quickly to any surface it drips on including skin. The smoke from polyester is black with a sweetish smell. The extinguished ash is hard.

- Rayon-burns rapidly and leaves only a slight ash. The burning smell is close to burning leaves.

So happy burning pyros, next week we will delve into labels.

Until then...

xoxo,

Caiti & Jess